Part V: The Weaver

The following post is Part V of our series: “Meet the Makers” tracking the production process of Avani’s indigo textiles from seed to scarf. For more information about the series and an introduction to the Avani blog, see our first post.

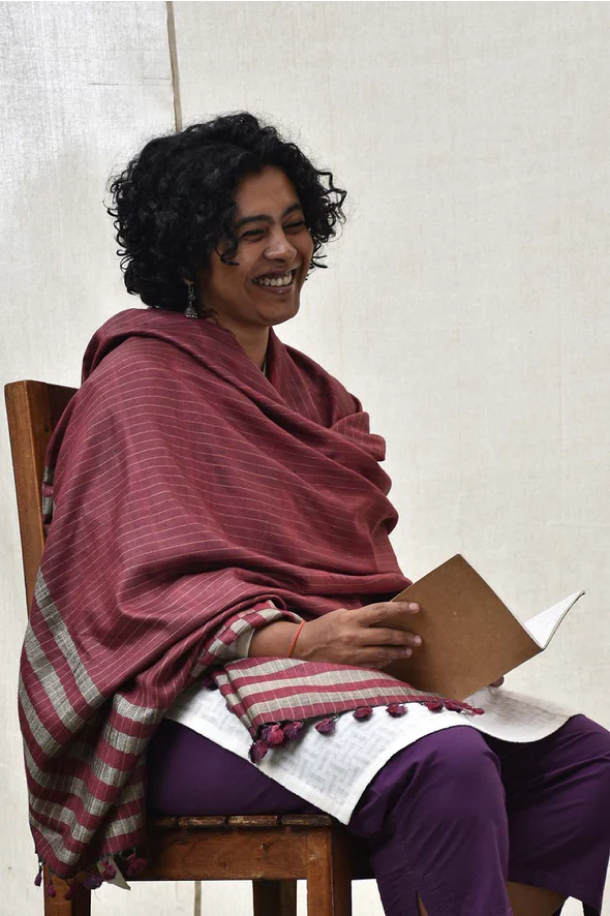

Sonam Arya has been working with Avani for 5 years as a weaver. Through Avani, Sonam has learned to make a range of textile products, including shawls, scarves, and mufflers.

Weaving is a highly complex process that can be difficult to understand from mere observation. In essence, weaving is composed of holding vertical threads (called warp) in tension while inter-weaving horizontal threads (called weft) in a predetermined pattern controlled by the manual lifting of the weft through foot pedals. Since starting work at Avani, Sonam has become proficient in a range of weaving techniques including warping (stretching the yarn in place in the loom prior to weaving) and reeling.

Sonam says that she works in the center primarily to provide for her family. She greatly enjoys the work that she does, and has learned a great deal about weaving from the older ladies at the center.

Login

Login